"Cupellation"

Cupellation

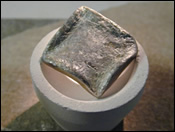

The lead buttons are placed into a cupel. Cupels are made of bone ash

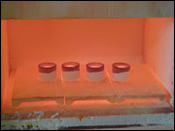

and cement or magnesium oxide. The cupels are loaded into the

cupellation kiln at 1750°F.

The

lead buttons are allowed to "open", that is to become molten. When the

cupellation is "driving" or the lead is being absorbed into the cupel

or driven off as lead oxide, the furnace is opened slightly to provide

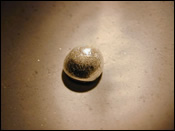

a draft. The lead is absorbed leaving behind a tiny doré bead

containing the gold and silver.

The cupels are allowed to cool.

The doré is then removed, brushed to remove any adhering cupel material

and flattened using an anvil and bead hammer. At this point the doré is

weighed.

The doré is then finished gravimetrically or by wet chemical digestion and analysis using Atomic Absorption Spectroscopy.

Parting and Annealing

Parting

If your bead appears to be relatively pure gold, no parting is

necessary. If the presence of a significant amount of silver and/or

PGMs is indicated, proceed as follows:

To part the silver from the gold, the button must contain at least 3 times as much silver as gold.

If it does not, add sufficient assay silver to make this ratio. This is called "inquartation.

If the analysis is to be finished gravimetrically the flattened doré is

placed in a porcelain parting cup. Nitric acid (15% v/v) is added to

the parting cup and heated on a hotplate. The nitric acid dissolves the

silver leaving behind a gold sponge. The sponge is washed three times

with de-ionized water and allowed to thoroughly dry.

Then proceed to "anneal" the button as follows:

Annealing

Anneal by repeatedly hammering the bead flat and heating it in a flame

until it's red hot. Repeat heating after every couple of blows with the

hammer.

The annealed strip is then rolled into a loose coil

or "coronet," placed in a parting cup and covered with a parting

solution, a mixture of chemically pure nitric acid and distilled water,

6 parts water to I part acid, or a 6/1 ratio.

Heat the flask gently. The coronet will blacken as the hydrogen bubbles off. Do not allow it to boil too fast.

If the coronet becomes immediately black, add a little more distilled water to slow the action.

Finish

Gravimetric Instrumental: GA-AAS

Calculations

Silver correction factor (c.f.) = blank inquart wgt. (mg.) /blank doré wgt. (mg.)> Gold (oz/st) = gold (mg.) x (29.167/sample wgt.) Silver (oz/st) = (((doré (mg.) - gold (mg.)) x c.f.)- inquart wgt.) x (29.167/sample wgt.)